In the evolving landscape of manufacturing technology, micro 3D printing has emerged as a groundbreaking method that is reshaping how intricate components are designed and produced. Also known as micro additive manufacturing (Micro AM), this advanced process enables the creation of objects with features as small as a few microns, something previously thought impossible with traditional 3D printing techniques. With cutting-edge technology and innovative design, micro 3D printing is transforming industries and opening doors to unprecedented possibilities.

Understanding Micro 3D Printing

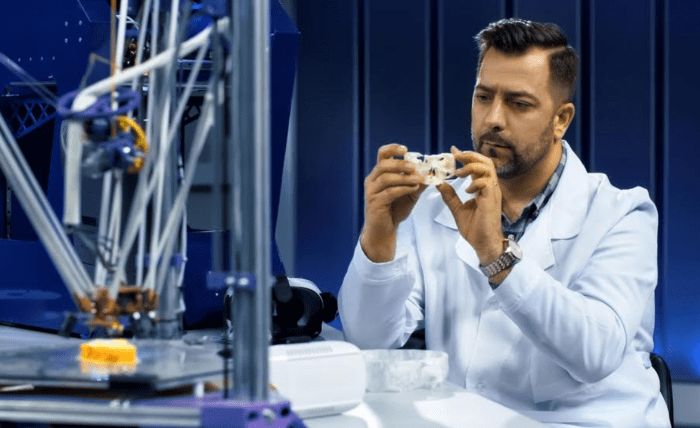

Micro 3D printing is a highly precise manufacturing technique that builds components layer by layer using photosensitive materials. Guided by data from 3D computer-aided design (CAD) software, modern micro 3D printers achieve remarkable resolutions—down to 1.5 microns in the X and Y dimensions. Parts are built up from successive layers of material as thin as 1-5 microns.

As an illustration of how fine this level of precision is, an individual red blood cell is 7 microns in diameter and an individual particle of smoke is about the same size as the minimum surface finish unevenness that the best Micro 3D printing techniques can deliver. This level of precision allows for the creation of intricate structures with unparalleled accuracy, making it a cornerstone for producing components at the micro-scale.

The process itself is a departure from traditional manufacturing methods like micro-molding, which often come with limitations in design complexity and material efficiency. By eliminating these constraints, a micro 3D printing service enables the production of freeform surfaces and complex geometries, empowering manufacturers to reimagine design possibilities and optimize production costs.

Applications of Micro 3D Printing

The versatility of micro 3D printing has fueled its adoption across a range of industries. Each uses the technology to create components with intricate designs and precise dimensions.

In the medical field, micro 3D printing has revolutionized the development of tools and devices used for diagnostics and treatment. Microfluidic devices, for instance, are critical for lab-on-a-chip applications, enabling researchers to conduct complex chemical and biological analyses on a small scale. Additionally, the technology facilitates the production of specialized instruments, such as those used to monitor neuronal activity, advancing both research and patient care.

The electronics industry has also embraced micro 3D printing because it can produce micro connectors and detailed prototypes, meeting the increasing demand for miniaturization in electronic devices. From consumer gadgets to sophisticated industrial equipment, this technology supports the rapid development of parts with precise geometries and complex designs, accelerating innovation.

In aerospace and automotive applications, micro 3D printing plays a vital role in manufacturing lightweight yet highly detailed components. By reducing material usage and enhancing part performance, the technology contributes to the creation of efficient and cost-effective designs for space exploration, aviation, and advanced vehicle systems.

Optics, too, has benefited from micro 3D printing, particularly in the production of micro-lens holders and intricate mounts required for optical assemblies. Researchers and developers can now prototype and refine these components with unmatched accuracy, ensuring superior functionality and performance.

The Future Potential of Micro 3D Printing

While micro 3D printing is already transforming industries, its future potential promises even greater advancements. As the technology evolves, it is expected to play a key role in enabling the production of microelectromechanical systems (MEMS). These systems, which include sensors and actuators, are fundamental to modern devices such as smartphones, medical implants, and autonomous vehicles.

Microfluidics is another area poised for growth. With micro 3D printing, researchers can produce tiny channels and structures essential for precise fluid control, advancing fields like drug delivery, environmental monitoring, and biotechnology. This capability is particularly important as industries increasingly focus on sustainability and efficiency.

Beyond these applications, the development of more advanced materials compatible with micro 3D printing will expand its reach. Materials with unique properties, such as biocompatibility or high thermal resistance, could unlock new possibilities in medical implants, high-performance electronics, and beyond.

Bridging Creativity and Manufacturing

Micro 3D printing represents more than just a technological breakthrough—it is a bridge between creativity and manufacturing. By enabling the realization of intricate designs with unparalleled precision, it empowers innovators to push the boundaries of what is possible. Whether prototyping experimental designs or manufacturing critical components, this technology is at the forefront of a new era in production.

For businesses and tech enthusiasts alike, the rise of micro 3D printing serves as a compelling example of how cutting-edge technology can reshape industries. As the technology matures and its applications expand, it promises to remain an exciting frontier for innovation in the years to come.