Are your warehouse operations taking longer than they should? Are errors in picking and packing causing delays and unhappy customers? Do you want to maximize your storage space and reduce operational costs? Improving warehouse efficiency is more important than ever in today’s fast-paced supply chain and e-commerce environment. An efficient warehouse reduces costs, improves order accuracy, speeds up delivery times, and enhances customer satisfaction. Achieving this requires smart planning, the right technology, and ongoing process improvement. This article explores practical strategies to make your warehouse operations faster, smarter, and more reliable.

Optimize Warehouse Layout

A well-designed warehouse layout is fundamental to efficiency. Poor layout planning can result in wasted time, excessive movement of goods, and bottlenecks in key areas such as picking and packing. To optimize layout:

- Use ABC Analysis: Categorize products based on demand and frequency of picking. High-demand items (A) should be placed near packing and shipping areas, while low-demand items (C) can be stored further away.

- Designate Clear Zones: Create specific areas for receiving, storage, picking, packing, and shipping. Clear zoning minimizes confusion and reduces travel time for workers.

- Consider Vertical Storage: Utilize vertical space with tall shelving and pallet racking to maximize storage capacity without expanding the warehouse footprint.

- Optimize Aisle Widths: Ensure aisles are wide enough for forklifts and pallet jacks but not so wide that they waste space. Narrow, well-organized aisles can improve storage density.

A strategic warehouse layout reduces unnecessary movement and streamlines workflows, making daily operations smoother.

Implement Inventory Management Systems

Effective inventory management is crucial for minimizing stockouts, overstocks, and lost items. Implementing an inventory management system (IMS) or warehouse management system (WMS) provides real-time visibility into stock levels and location, which can significantly improve operational efficiency. Key considerations include:

- Barcode or RFID Technology: Automate inventory tracking with barcodes or RFID tags to reduce manual errors and speed up data entry.

- Automated Replenishment: Set up automatic alerts or orders when stock levels fall below predefined thresholds to prevent stockouts.

- Cycle Counting: Replace full inventory counts with cycle counting, where small portions of inventory are checked regularly. This reduces disruption and ensures ongoing accuracy.

- Data Analytics: Use historical data to forecast demand, optimize reorder points, and make informed purchasing decisions.

Accurate inventory management not only prevents costly errors but also ensures that workers spend less time searching for products.

Streamline Picking and Packing Processes

Picking and packing are often the most labor-intensive tasks in a warehouse. Improving these processes can dramatically boost efficiency. Consider these strategies:

- Batch Picking: Combine orders that contain similar items into batches to reduce trips across the warehouse.

- Zone Picking: Assign workers to specific zones, allowing them to specialize in picking products in their area.

- Pick-to-Light and Voice Picking: Use technology such as pick-to-light systems or voice-directed picking to guide workers to items quickly and accurately.

- Standardized Packing Stations: Organize packing materials, labels, and shipping tools at each station to reduce delays. Standardize packing procedures to ensure consistency and accuracy.

When selecting equipment for moving heavy items, always choose a forklift service that is reliable and properly maintained to prevent downtime. By reducing travel time, errors, and unnecessary movements, streamlined picking and packing processes can significantly increase throughput.

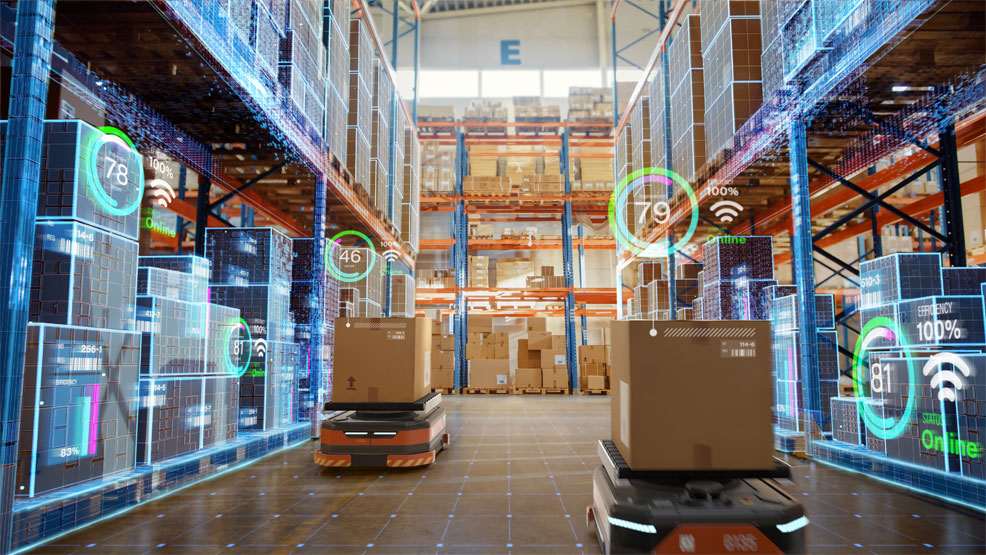

Invest in Automation

Automation has transformed modern warehouses by reducing manual labor, improving speed, and enhancing accuracy. While the level of automation depends on the size and type of warehouse, some common options include:

- Automated Storage and Retrieval Systems (AS/RS): Use robotic systems to retrieve and store products efficiently, reducing manual picking.

- Conveyor Systems: Move products between receiving, storage, and shipping areas automatically.

- Sorting Systems: Automate order sorting for faster fulfillment, particularly in high-volume e-commerce operations.

- Collaborative Robots (Cobots): Support human workers by handling repetitive or heavy tasks, such as palletizing or transporting goods.

Investing in the right automation tools can reduce labor costs, minimize errors, and allow staff to focus on higher-value tasks.

Improve Workforce Productivity

Even with advanced technology, the human workforce remains central to warehouse efficiency. Ensuring employees are well-trained, motivated, and equipped to perform their tasks effectively is essential. Steps to improve workforce productivity include:

- Training Programs: Offer comprehensive onboarding and ongoing training for new technologies, safety procedures, and warehouse best practices.

- Performance Metrics: Track KPIs such as orders picked per hour, error rates, and on-time shipments to identify areas for improvement.

- Ergonomic Workstations: Design workstations to reduce strain and fatigue, which can improve speed and accuracy.

- Employee Engagement: Encourage feedback and reward high performance to boost morale and motivation.

A skilled, motivated workforce contributes directly to smoother warehouse operations and higher efficiency.

Implement Lean Principles

Lean methodology focuses on eliminating waste and continuously improving processes. In a warehouse context, this can be applied by:

- Reducing Motion Waste: Arrange workstations and storage locations to minimize unnecessary walking or movement.

- Minimizing Waiting Times: Ensure that processes flow smoothly without delays, such as immediate unloading of incoming shipments.

- Standardizing Procedures: Develop standard operating procedures (SOPs) for key tasks to reduce errors and variability.

- Continuous Improvement: Encourage employees to identify inefficiencies and suggest improvements.

Applying lean principles fosters a culture of efficiency and continuous optimization.

Utilize Data for Decision-Making

Data-driven decision-making allows warehouses to operate more efficiently and anticipate potential issues before they escalate. Some ways to leverage data include:

- Warehouse Analytics Dashboards: Monitor metrics such as order cycle times, inventory turnover, and labor utilization.

- Predictive Analytics: Forecast demand fluctuations and adjust staffing and inventory levels accordingly.

- Root Cause Analysis: Investigate recurring inefficiencies or errors and implement corrective actions.

Using data to guide operational decisions ensures resources are allocated effectively and inefficiencies are addressed proactively.

Enhance Safety and Organization

A safe, organized warehouse is inherently more efficient. Accidents, clutter, and disorganization can slow operations and increase costs. Strategies include:

- Clear Signage and Labeling: Mark aisles, zones, and storage areas clearly to reduce confusion.

- Regular Maintenance: Keep equipment and machinery in good condition to prevent breakdowns.

- Safety Protocols: Train employees on safe handling, lifting, and equipment use to minimize accidents.

- 5S Methodology: Sort, Set in order, Shine, Standardize, and Sustain to maintain a clean and organized environment.

An organized warehouse reduces downtime, improves workflow, and supports a productive workforce.

Optimize Shipping and Receiving

Efficient inbound and outbound processes are essential for overall warehouse efficiency:

- Scheduled Deliveries: Coordinate delivery times with suppliers to prevent congestion in receiving areas.

- Cross-Docking: Move products directly from receiving to shipping when possible, reducing storage time.

- Consolidate Shipments: Group orders going to the same destination to minimize shipping costs and handling.

Streamlining shipping and receiving ensures smooth movement of goods through the warehouse and faster order fulfillment.

Conclusion

Improving warehouse efficiency is not a one-time task; it requires continuous evaluation, adaptation, and innovation. By optimizing warehouse layout, implementing robust inventory management, streamlining picking and packing, adopting automation, training staff, applying lean principles, leveraging data, enhancing safety, and refining shipping and receiving processes, businesses can significantly enhance operational efficiency. These improvements lead to reduced costs, faster fulfillment, higher accuracy, and ultimately, better customer satisfaction. In a competitive market, an efficient warehouse is not just an operational advantage—it is a strategic asset.